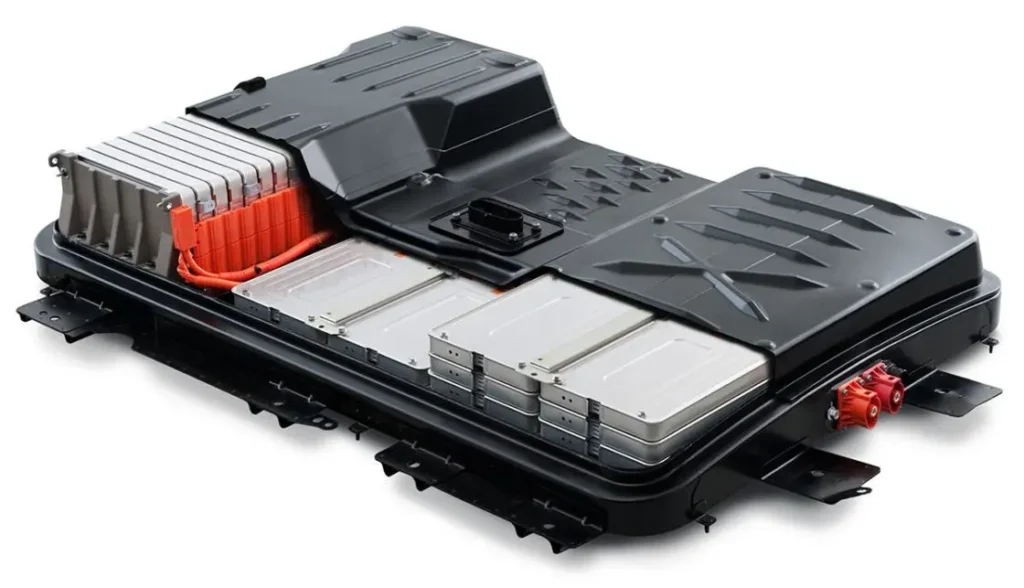

Electric cars have revolutionized the transportation industry by providing a cleaner, more sustainable mode of transportation. The driving force behind electric cars is the battery technology that powers them. Lithium-ion batteries are the most commonly used type of battery in electric cars today, and they rely on a range of materials such as lithium, cobalt, and nickel. In this article, we will take a deep dive into the electric car battery industry and explore the materials that make up these batteries.

Lithium-Ion Batteries

Lithium-ion batteries are the most commonly used type of battery in electric cars today. They are lightweight, have a high energy density, and are rechargeable. Lithium is a key component of these batteries, and it is extracted from brine pools or underground deposits in countries such as Chile, Argentina, and Australia. Once extracted, the lithium is processed and refined before being used in battery production.

Cobalt

Cobalt is another important component of electric car batteries. It is used to increase the stability of the battery and improve its performance. Cobalt is typically mined in countries such as the Democratic Republic of Congo (DRC), which produces over 60% of the world’s cobalt. However, the mining of cobalt has been linked to human rights abuses and environmental damage in the DRC, leading some companies to look for alternative materials.

Nickel

Nickel is also commonly used in electric car batteries. It is used to increase the energy density of the battery, which allows it to store more energy and provide a longer driving range. Nickel is primarily mined in Canada, Russia, and Indonesia.

Other Materials

In addition to lithium, cobalt, and nickel, electric car batteries also contain other materials such as manganese and graphite. Manganese is used to improve the stability of the battery, while graphite is used as a conductor in the battery’s electrodes.

Industry Challenges

The electric car battery industry faces a number of challenges, including the availability and cost of raw materials. As demand for electric cars continues to increase, there is a growing concern about the availability of materials such as cobalt and nickel. This has led some companies to explore alternative materials, such as iron or aluminum, that could be used in place of these materials.

Another challenge facing the industry is the environmental impact of battery production and disposal. Battery production requires significant amounts of energy, and the disposal of batteries at the end of their life cycle can be harmful to the environment if not properly managed.

The electric car battery industry is a critical component of the sustainable transportation movement. Lithium-ion batteries are the most commonly used type of battery in electric cars today, and they rely on a range of materials such as lithium, cobalt, and nickel. The industry faces a number of challenges, including the availability and cost of raw materials and the environmental impact of battery production and disposal. As the industry continues to evolve, it will be important to develop new technologies and materials that can meet the growing demand for sustainable transportation while minimizing the industry’s impact on the environment.